Langcourt is recognized as the worldwide leader in the plating and repairing of aluminum cylinders. For over 30 years it has offered its wealth of experience and expertise to the most demaning customers in the world. Including F1 Engine Manufacturer COSWORTH and several top MXGP Teams including the Monster Energy Yamaha and the Bike It Cosworth Yamaha.

1. Technical Superiority

LANGCOURT remains on the cutting edge of cylinder technology. Our engineering background combined with many years of experience has helped us master processes said to be impossible by our competitors. LANGCOURT continues to welcome new challenges and development projects with confidence.

2. Our Nickel-Silicone-Carbide Coating

Our coating on the bore is Nickel Silicon Carbide which is a composite coating of Nickel and Silicon Carbide evenly dispersed throughout. The silicon carbide acts as the running and wear surface and the nickel serves as the bonding agent. All of these factors result in having a longer lasting, cooler running and more importantly a more powerful engine.

The benefits of the coating over cast iron include:

- Better heat transfer

- 10 times more wear resistance

- Better oil retention

- Lower coefficient of friction

3. Our Honing Process

No cylinder would be complete without a proper honed finish. Honing not only sets up the bore so the piston will not seize, but also affects the ring seal and ring wear. The honing is even more important when finishing a nickel silicon carbide cylinder. At LANGCOURT we use only the best German diamond tooling from GEHRING and check our cylinders with a surface roughness tester. The surface finish determines cylinder life and oil retention. It also can affect ring compatibility. The result of all our technology is the roundest, straightest and longest wearing cylinder bores on the worldwide market.

4. The Benefits:

- Increased horsepower

- Less weight than cast iron

- Improved heat transfer

- Greater ring compatibility

- Factory bores available

- Saves custom porting

- Return to stock size

- Superior wear resistance

- Improved port chamfers

- Saves on cost for new cylinders

- Technical support

- Quick turn-around ( usually 10 working days )

5. The Process

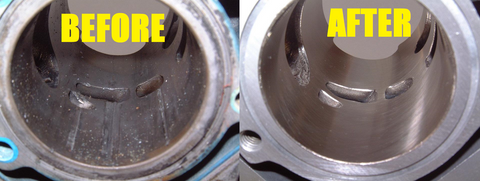

The process of repairing and replanting is by no means a simple process but properly performed it will renew the cylinder and the heart of any engine. All the steps are shown below.

Cylinder Inspection

We receive your cylinder and inspect it´s original condition.

Bead Blasting

The blasting process removes oil and carbon.

Stripping old plating

A very strong chemical is used to dissolve the old Steel and Nickel.

Welding

Material is added to the surface to fill in the surface.

Cleaning

The entire surface is completely evened out before any work starts.

Boring

Bore to even the surface prior to the welding.

Welding

Extra material is added to the cylinder walls.

Boring

Bore to clean the welds or for a big bore piston kit.

Honning

Removes all the tool marks and prepare the surface for plating.

Plating

Plating the cylinder with nickel silicon carbide.

Honing

Honing the cylinders plating with diamond tooling.

For cylinder repairs and replating please contact us. Buying this product is only a reference to start working with your cylinder, actual costs are based on original condition of the cylinder and whether or not there is internal damage after the original plating is removed.